Manufacturing Process

Advanced Manufacturing Capabilities

Our 40,000+ square meters of manufacturing facilities house complete production capabilities for aluminum heat exchangers, from raw material processing through final assembly and testing. Our vertically integrated approach ensures quality control at every step.

Manufacturing Steps

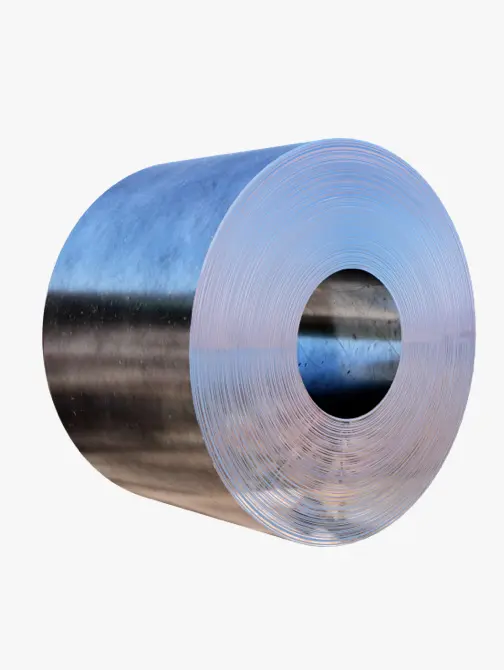

Material Preparation

High-quality aluminum alloy sheets and tubes are inspected and prepared for processing.

- • Incoming material inspection

- • Chemical composition verification

- • Material slitting and cutting

- • Full lot traceability

Fin Manufacturing

High-speed fin forming lines create precision fin geometries for optimal heat transfer.

- • Louvered, offset, and plain fins

- • Custom fin heights and pitches

- • Precision tooling for consistency

- • High-speed automated production

Core Assembly

Fins and tubes are precisely stacked and assembled using fixture-based assembly techniques.

- • Precision fixture stacking

- • Header and tank assembly

- • Tube insertion and forming

- • Pre-brazing inspection

Brazing Technology

Advanced CAB and vacuum brazing for superior joint quality and corrosion resistance.

CAB Brazing

High-volume, consistent quality for radiators and CACs

Vacuum Brazing

Flux-free, clean joints for oil coolers

Welding & Assembly

Robotic and manual welding for connections, fittings, and modular pack integration.

- • Robotic MIG/TIG welding

- • Manual precision welding

- • Fitting and connection assembly

- • Modular cooling pack integration

Testing & Finishing

100% leak testing, cleaning, and final inspection before packaging.

- • 100% air/helium leak testing

- • Multi-stage cleaning

- • Visual and dimensional inspection

- • Protective packaging

Key Manufacturing Equipment

Schedule a Factory Tour

We welcome OEM customers and partners to visit our manufacturing facilities. See our production capabilities and quality systems firsthand.

Request Factory Visit