Project Background

A major wind turbine OEM was developing a new 4.5 MW platform for both onshore and offshore applications. They required a complete thermal management solution that could handle multiple cooling circuits while meeting strict space, weight, and reliability requirements.

The Challenge

Technical Requirements

- Generator cooling: 150 kW heat rejection, liquid-cooled

- Gearbox oil cooling: 200 kW heat rejection, oil-to-air

- Converter cooling: 80 kW heat rejection, liquid-cooled

- Hydraulic system: 30 kW heat rejection for pitch/yaw

Constraints

- Limited nacelle volume (fixed envelope)

- Total weight budget: 1,200 kg

- Noise limits for onshore installations

- 20-year design life with minimal maintenance

- Offshore corrosion resistance required

Our Solution

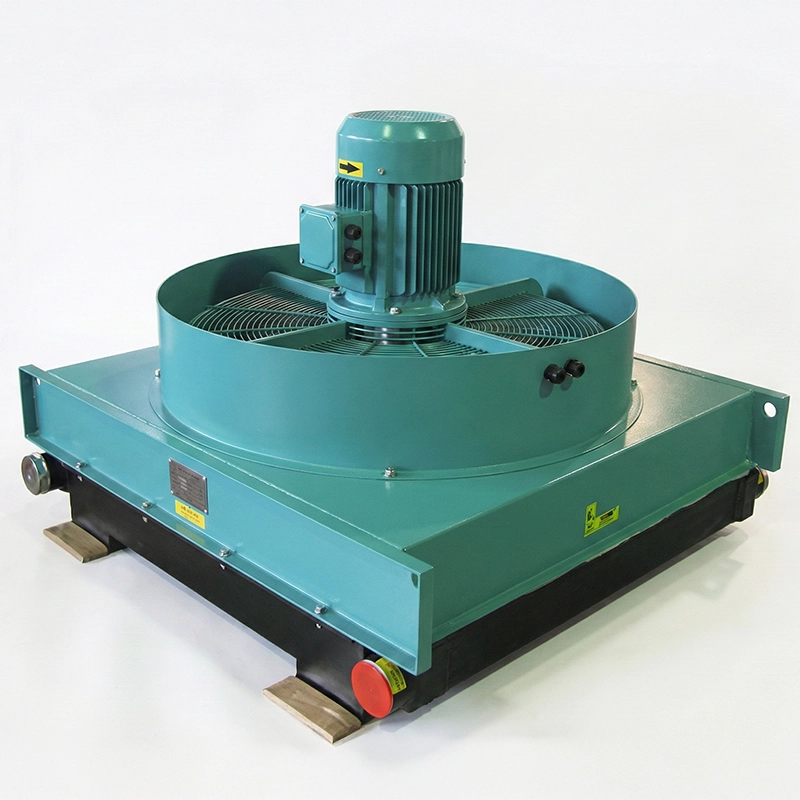

System Architecture

XinSheng developed an integrated nacelle cooling module that addressed all thermal circuits in a single, optimized package:

Primary Heat Exchanger Assembly

- Water-glycol cooled radiator for generator and converter circuits

- Shared cooling fan system with variable speed control

- Oil-to-air cooler for gearbox with separate thermal circuit

Design Innovations

- Compact Package: Multi-circuit integration reduced total volume by 35%

- Weight Optimization: Aluminum construction with strategic reinforcement

- Serviceability: Modular design for component replacement

- Durability: Marine-grade coatings for offshore protection

Validation Testing

Products underwent extensive testing:

- 500+ hours of thermal cycling

- Salt spray testing (2,000 hours)

- Vibration endurance (equivalent to 20-year life)

- Full thermal performance validation in climate chambers

Results

After 5 years of field operation across 500+ turbines:

| Performance Metric | Target | Achieved |

|---|---|---|

| System Uptime | 99% | 99.5% |

| Thermal Performance | Meet specs | Exceeded by 10% |

| Weight | 1,200 kg | 1,150 kg |

| Service Life | 20 years | On track |

| Maintenance Interval | 5 years | Extended to 10 years |

Long-Term Reliability

Zero cooling-related failures reported in:

- 250+ onshore turbines (Germany, USA, China)

- 250+ offshore turbines (North Sea, Taiwan)

Products Used

- Integrated Nacelle Cooling Module - Custom multi-circuit heat rejection system

- Gearbox Oil Cooler - Bar & plate construction for high reliability

- Liquid-to-Liquid Heat Exchanger - Generator and converter thermal management

Engineering Support

XinSheng provided comprehensive engineering support:

- Early-stage CFD analysis and thermal modeling

- Prototype development and testing

- Design validation and PPAP documentation

- Production tooling and quality systems

- Ongoing technical support

Applicable Platforms

This solution approach applies to:

- Onshore wind turbines (2-6 MW)

- Offshore wind turbines (all platforms)

- Industrial gearbox cooling applications

- High-reliability power generation systems

Partnership

This project demonstrates XinSheng’s capability as a development partner for demanding wind power applications. Contact us to discuss your nacelle cooling requirements.